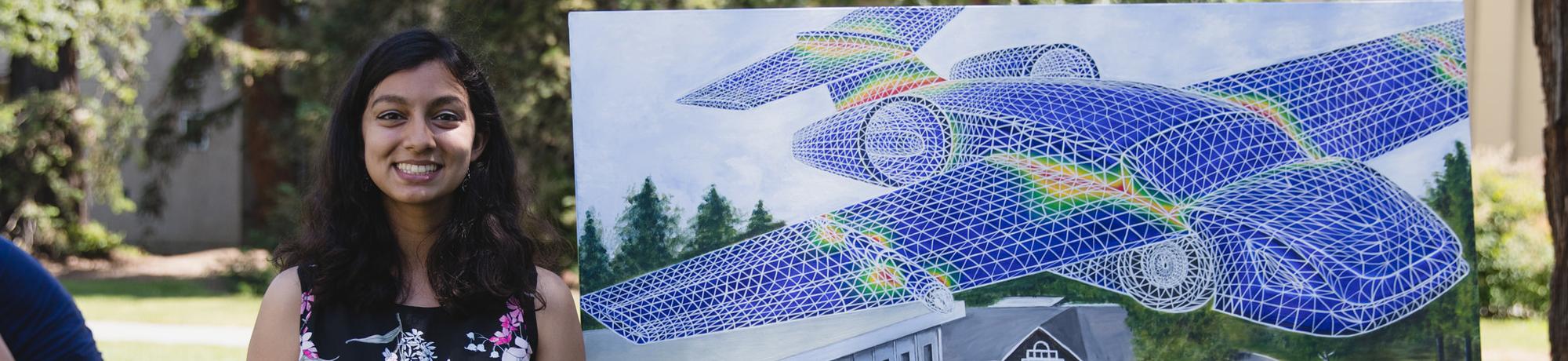

Design involves the creative use of all the basic engineering sciences to conceive practical devices that satisfy a prescribed functional specification. Design typically involves iteration between “synthetic” and “analytic” phases, the former being concerned with conceptualization of basic operating principles, and the latter with detailed sizing of parts and selection of materials. Software tools for computer aided geometric design, finite element analysis and dynamic simulations play a central role in engineering design. Manufacturing involves the selection of basic part fabrication processes (such as casting, machining, forming, or molding) consistent with the desired part characteristics and costs. Computer controls play a central role in modern manufacturing, to ensure consistent part accuracy with high throughput. Design for manufacturability, maintenance, extended service life, disposability, and many other considerations are key concerns of modern industry. Micro-electromechanical systems (MEMS) and nanostructures includes optical nanostructures and optical MEMS, physical sensors, and microfluidic devices.

Design, Manufacturing, MEMS and Nanostructures

Design, Manufacturing, MEMS and Nanostructures Faculty

Harry H. Cheng

Position Title

- Professor

Cristina Davis

Position Title

- Professor

- Associate Vice Chancellor of Interdisciplinary Research and Strategic Initiatives

Mohsen Habibi

Position Title

- Assistant Professor

Michael R. Hill

Position Title

- Professor

Barbara Linke

Position Title

- Professor

Bahram Ravani

Position Title

- Distinguished Professor

Nesrin Sarigul-Klijn

Position Title

- Professor

Masakazu Soshi

Position Title

- Professor