Graduate student team develops COVID-19 vaccine distribution plans for Northern California

As the FDA approves COVID-19 vaccines for use, distribution to hospitals and vaccination sites will become the next challenge in fighting the pandemic. As part of their “Optimization-Based Control” (MAE 298) course, a group of mechanical and aerospace engineering (MAE) graduate students were inspired to help and developed efficient vaccine distribution plans for the Bay Area and Sacramento using three different types of delivery vehicles.

The group—comprised of M.S. students Monica Torralba, Jonathan Boyd and Evan Foley—decided to tackle vaccine distribution for their class project to apply optimization-based control techniques. They were excited by the timeliness of the problem, and also by their shared interest in transportation.

“I thought it was very interesting to compare the old school van with the drones, and we also explored the middle ground, which were these little last-mile autonomous cars called UGVs,” said Boyd.

Assuming enough doses were available, they calculated the range and carrying capacity of each vehicle and the weight of the vaccine to estimate how many doses each could carry. They then mapped the coordinates of the more than 60 hospitals in each region and estimated the number of vaccines each would need, given the number of workers and hospital beds at each location.

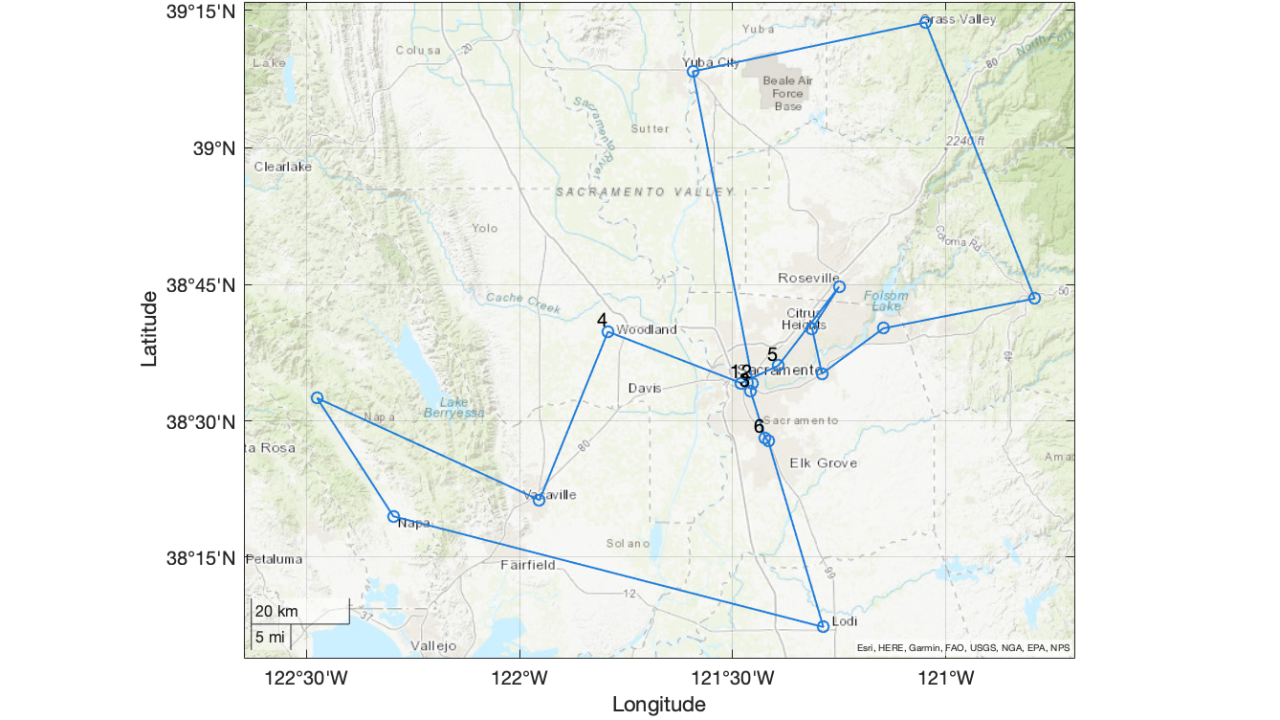

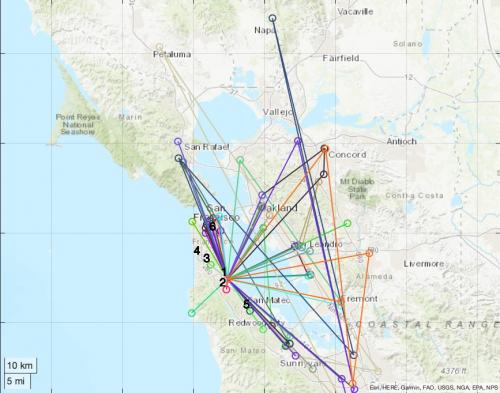

They fed this data into a savings algorithm, which is used to solve the “traveling salesman” problem of how to visit several points in the shortest possible route before returning to the start. The group used the San Francisco, Oakland and Sacramento airports as starting points, as vaccines will likely arrive by plane.

The algorithm looked at the distance to each hospital and between hospitals, and if one hospital was near another one, it turned two trips into one. It did this until each vehicle hit its capacity or range constraints, at which point it generated the final route. The group had the algorithm generate routes for all three vehicles and for each metropolitan area and estimated the number of vehicles that would be needed in each situation.

They found that drones were fast and effective, but limited by their 3-pound carrying capacity and short range.

“It only takes three hours to deliver by drone, but you need almost an armada to take advantage of this,” said Boyd. “I think that’s your biggest tradeoff—you can either do this with one cargo van or three of the autonomous vehicles or 40 of the drones.”

Vans were best for the more spread-out Sacramento region because of their longer range, larger carrying capacity and refrigeration capability, which is needed for some vaccines. The UGVs offered a middle-ground solution. Despite their limited top speed, their small size and refrigeration capability make them adaptable to dense and traffic-congested areas like Oakland or San Francisco.

“The project perfectly demonstrates how some of the engineering techniques we have learned in lectures can be used to solve real world problems,” said their instructor, associate professor Zhaodan Kong. “The students were also willing to spend extra effort getting all the necessary data for their project, which is a process that is very time consuming and often overlooked.”

Though the project is a preliminary study, the group hopes that it can inspire distribution plans for COVID-19 or future situations where medical supplies are urgently needed. They would like to see future work build on their findings and factor in refueling stops and vehicle reuse, account for vaccine packaging weight and find ways to make the three vehicles work in concert to deliver doses.

“I think the project really highlights the advantage of these drones and kind of last-mile vehicles,” said Boyd. “And if this is not the last pandemic, this distribution network definitely could be an angle of improvement.”